APX RAPID MANUFACTURING

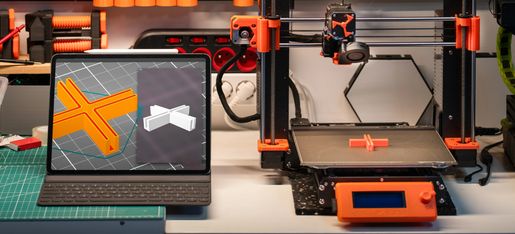

At APX Rapid, we specialize in producing anywhere from 1 to 20,000+ precision-engineered parts with lead times as short as 1 day. Our production fleet of HP Multi-Jet Fusion 5210 Pro printers allows us to deliver complex geometries, superior quality, and unmatched speed.

Our core technology, the HP Multi Jet Fusion 5200 series, offers the lowest cost per part, fastest throughput, and most consistent quality of any 3D printing platform on the market — enabling 24/7, true high-volume production.

3D Printing Services

High-quality prints

Our state-of-the-art 3D printers are capable of producing high-quality prints with intricate details, smooth surfaces, and vibrant colors. Whether you need a prototype or a finished product, we've got you covered.

Fast turnaround time

We understand that time is money, and that's why we pride ourselves on our quick turnaround time. Our efficient production process ensures that you receive your prints in a timely manner, without compromising on quality.

Cleanroom Grade Parts Requirements

Cleanroom Grade Parts Requirements

Cleanroom Grade Parts Requirements

Material Selection

- Use materials with low particle shedding and non-outgassing properties (e.g., stainless steel, PEEK, PTFE, anodized aluminum).

- Avoid porous or friable materials that can trap contaminants.

Surface Finish

- Parts must be smooth, polished, burr-free, and free of pits or cracks.

- Stainless steel parts often require passivation or electropolishing.

Cleaning Standards

- Parts should be cleaned to ISO 14644 cleanroom standards or per customer specifications (e.g., MIL-STD-1246C, IEST-STD-CC1246D).

- Final cleanliness levels may be specified as Level 50, 100, or stricter depending on application (semiconductors, aerospace, medical).

Inspection & Verification

- Visual inspection under cleanroom conditions.

- Particle count and non-volatile residue (NVR) testing.

- Documentation of compliance (cleanliness certificate).

Clean Packaging Requirements

Cleanroom Grade Parts Requirements

Cleanroom Grade Parts Requirements

Packaging Environment

- Packaging must be performed inside a certified cleanroom (ISO Class 5–7).

- Operators should wear full cleanroom garments (bunny suits, gloves, masks, booties).

Primary Packaging

- Use polyethylene, nylon, or cleanroom-certified bags.

- Double or triple bagging is required for semiconductor, aerospace, and medical components.

- Bags must be heat-sealed, not zip-locked.

Secondary Packaging

- Place double-bagged parts into clean, static-dissipative containers or boxes.

- Use clean cushioning (e.g., clean foam or Tyvek sheets) if necessary.

Labeling

- Labels must be cleanroom-compatible and non-particulating.

- Include part number, cleanliness level, date of cleaning/packaging, and batch/lot number.

Handling & Shipping

- Handle parts only with powder-free gloves.

- Ship in certified clean transport boxes or crates.

- Use desiccants or nitrogen purging for sensitive optics/electronics.

At APX Rapid Manufacturing, we believe speed and precision should never come at the expense of quality. By combining advanced 3D printing technology with expert engineering, we deliver production-ready parts that empower businesses to innovate faster, scale smarter, and compete stronger. Whether it’s a single prototype or a high-volume production run, our mission is the same—to turn your vision into reality with reliability, speed, and excellence.

Bring Your Ideas to Life

Let us bring your ideas to life with precision and speed.

ORDER TODAY

Call NowThis website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.