Company Summary

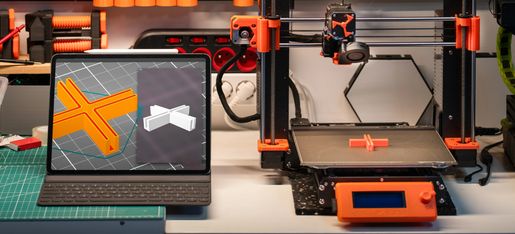

APX Rapid is a high-precision prototyping and advanced manufacturing firm committed to transforming ideas into reality with speed, accuracy, and scale. Using cutting-edge additive manufacturing technologies—fueled by a powerful fleet of HP Multi Jet Fusion printers—APX Rapid delivers both prototype and production-grade components for businesses across industries.

We specialize in rapid turnarounds, design optimization, and strict quality standards, including cleanroom compliance and ESD-safe material handling. Our dedication to innovation ensures that every part we produce meets the highest levels of performance, finish, and function.

Matthew Martin

Chief Executive Officer | Lead Engineer

📞 +1 512-501-2723 Ext: 703

📱 +1 210-246-2561 (Cell)

✉️ Matt@APXrapid.com

Matthew specializes in Design for Additive Manufacturing (DFAM). He helps customers optimize their parts for lower costs, tighter tolerances, and faster production.

Lorenzo Trevino

Chief Operating Officer | Lead Engineer

📞 +1 512-501-2723 Ext: 704

📱 +1 210-867-8142 (Cell)

✉️ Lorenzo@APXrapid.com

Lorenzo manages APX Rapid’s prototyping workflow, from concept to finished part. His focus is speed and accuracy, ensuring that clients receive working prototypes in record time.

Our Process

At APX Rapid, our process is designed to move ideas from concept to production seamlessly. We begin by collaborating closely with clients to understand their vision, technical requirements, and end-use goals. From there, our engineering team applies advanced design-for-additive principles to optimize each part for performance, cost efficiency, and scalability.

Using state-of-the-art HP Multi Jet Fusion technology, we deliver prototypes and production runs with unmatched speed and precision. Every step—from material selection to post-processing and quality assurance—is carefully managed to ensure consistency, reliability, and customer satisfaction.

Our Strength

Our strength lies in the fusion of innovation, technology, and expertise. With a robust fleet of industrial-grade printers, a highly skilled team, and a commitment to pushing boundaries, we are uniquely positioned to handle projects ranging from single prototypes to high-volume manufacturing.

We excel at delivering tight tolerances, complex geometries, and industry-specific requirements such as cleanroom compliance and ESD-safe parts. Beyond technology, our strength is in the trust we build with our partners—through speed, quality, and solutions that empower them to scale with confidence.

ORDER TODAY

Call NowThis website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.